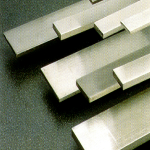

Aluminium

1100

Specifications

- 1100

Summary

- Widely used in fin stock

- Heat exchanger fins

- Spun hollow ware

- Dials and name plates

- Decorative parts

- Giftware

- Cooking utensils

- Rivets

- Reflectors

- Sheet metal work

- Greyish-white in colour, it is malleable, ductile and conductive to heat and electricity

- A thin inert film of oxide protects the metal surface from further attack, thus giving the metal a form of resistance to corrosion.

- This film of oxide can be further thickened by a process known as the anodizing

- Welding can be made possible.

- Anodized or spray coating possible to achieve different architectural effects

- With its non-corrosive and good mechanical properties, each grade of Aluminium has a high range of applications.

- Aluminium also possesses very high malleability, enabling it to be produced into a very thin foil.

Introduction:

Aluminum 1100 is a commercially pure aluminum alloy known for its excellent formability, corrosion resistance, and high thermal conductivity. Composed primarily of aluminum (Al) with small amounts of other elements, aluminum 1100 offers a unique set of characteristics that make it highly versatile and widely used in various industries. Here's a detailed write-up on aluminum 1100:

Composition:

Aluminum 1100 is a commercially pure aluminum alloy, typically containing:

- Aluminum (Al): 99.0% minimum

- Silicon (Si): ≤0.95%

- Iron (Fe): ≤0.05%

- Copper (Cu): ≤0.05%

- Manganese (Mn): ≤0.05%

- Zinc (Zn): ≤0.10%

- Titanium (Ti): ≤0.10%

- Other elements: ≤0.15% each, ≤0.05% total

The precise composition may vary slightly depending on specific manufacturing requirements and standards.

Properties:

- Excellent Formability: Aluminum 1100 exhibits exceptional formability, allowing it to be easily bent, shaped, and formed into various configurations. It can be cold worked to produce intricate designs and complex shapes without undergoing significant loss of ductility, making it suitable for deep drawing and spinning operations.

- Corrosion Resistance: Aluminum 1100 offers good corrosion resistance in both natural and industrial environments. It forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. While not as corrosion-resistant as some other aluminum alloys, it is still suitable for applications where moderate corrosion resistance is sufficient.

- High Thermal Conductivity: Aluminum 1100 has excellent thermal conductivity, making it suitable for heat transfer applications. It is commonly used in heat exchangers, radiators, and HVAC systems where efficient heat dissipation is essential.

- Electrical Conductivity: Aluminum 1100 exhibits good electrical conductivity, making it suitable for electrical conductor applications. It is used in wiring, cables, busbars, and electrical components where conductivity and lightweight properties are required.

- Low Strength: Aluminum 1100 is a soft and low-strength alloy compared to other aluminum alloys. While it offers good formability and corrosion resistance, it may not be suitable for applications requiring high mechanical strength or load-bearing capacity.

- Weldability: Aluminum 1100 is readily weldable using various welding techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. It forms strong and durable welds with proper welding procedures and techniques.

Applications:

- Sheet Metal Fabrication: Aluminum 1100 is commonly used in sheet metal fabrication for producing panels, enclosures, signage, and architectural elements. Its excellent formability and corrosion resistance make it suitable for a wide range of applications requiring lightweight and durable materials.

- Packaging: Aluminum 1100 is utilized in packaging applications for manufacturing foil, containers, and packaging materials. Its formability, corrosion resistance, and barrier properties make it suitable for protecting and preserving food, pharmaceuticals, and other consumer goods.

- Heat Transfer: Aluminum 1100 is employed in heat transfer applications such as heat exchangers, radiators, and HVAC systems. Its high thermal conductivity allows for efficient heat dissipation and temperature regulation in various industrial and automotive applications.

- Electrical Conductors: Aluminum 1100 is used in electrical conductor applications for manufacturing wiring, cables, busbars, and electrical components. Its high electrical conductivity and lightweight properties make it ideal for electrical transmission and distribution systems.

- Reflective Surfaces: Aluminum 1100 is utilized in reflective surfaces such as mirrors, lighting fixtures, and decorative finishes. Its bright, reflective surface enhances light reflection and visibility in architectural, automotive, and decorative applications.

- Chemical and Food Processing: Aluminum 1100 finds applications in chemical and food processing equipment for manufacturing tanks, vessels, and piping systems. Its corrosion resistance and inertness make it suitable for containing and transporting corrosive chemicals and food products.

Conclusion:

Aluminum 1100 is a commercially pure aluminum alloy known for its excellent formability, corrosion resistance, and thermal conductivity. Its versatility and wide range of applications make it indispensable in various industries, including automotive, aerospace, packaging, construction, electrical, and chemical processing. Whether in sheet metal fabrication, packaging, heat transfer, electrical conductors, reflective surfaces, or chemical processing equipment, aluminum 1100 continues to demonstrate its value as a lightweight, durable, and cost-effective material choice.

Share